- Home Page

- Company Profile

-

Our Products

- Essential Oil Extracting And Distillation Machine

- Pogostemon Cablin Essential Oil Distiller Extraction Machine

- Rosemary Essential Oil Distiller

- 100L Top Grade Industrial Palm Essential Oil Extraction Machine

- 20% Off Multipurpose Essential Oil Extractor

- Honey Concentration Machine

- Thinner Distillation Machine

- Full Plant Mango Juice Machine

- Essential Oil Extraction Equipment

- Rose Oil Extraction Machine Essential Extraction Machine

- Rosemary Oil Extraction Machine

- Tea-Tree Oil Extraction Machine

- Super-Critical Fluid Extraction

- Hempseeds Co2 Distillation Oil Extract Machine

- Burdock Seed Oil Extractor

- Countercurrent Circulation Ultrasonic Extraction And Concentration Machine

- Industrial Herb Ultrasonic Essence Extraction Machine

- High Quality Essential Oil Distiller Equipment

- Dairy Milk Ice Cream Processing Line

- Soy Milk Filling Machine

- Small Disc Type Milk Centrifuge Separator

- Industrial Milk Cream Fat Separating Equipment

- Milk Cream Centrifuge Separator

- 5000 Ltr CIP Cleaning Machine

- Farm Milk Cooling And Storage tank

- 3000 Ltr Horizontal Type Milk Cooling Tank

- Small Milk Plant Uht Milk Sterilizer Machine

- UHT Milk Processing Line

- UHT Milk Production Line

- Small Dairy Juice Drinks Pasteurizer Machine

- Milk Pasteurization Machine

- Stainless Steel Milk Pasteurization Machine

- Milk Cream Separator

- Factory Price GENYOND Milk Processing Line

- Fruit Leather Roll Up Making Machine

- Automatic Fruit Roll Up Scraping Forming Drying Cutting Making Processing Machine

- Fruit Leather Fruit Roll Up Machine

- Fruit Leather Production Line

- Fruit Leather Cut Machine

- Dehydrated Hawthorn Fruit Leather Production Line

- Fruit Leather Hawthorn Sweetend Roll Processing Line

- Automatic Fruit Leather Cutting Machine Production Line

- Fruit Leather Bar Roll Up Pulping Scraping Forming Cutting Making Machine

- Fruit Bar Fruit Leather Production Line Plant

- Fruit Leather Production Line

- Fruit Leather Making Machine

- Fruit Leather Making Machine

- Fruit And Vegetable Processing Machine

- French Fries Cutting Machine

- French Fries Making Machine

- French Fries Production Line

- Customized Passion Fruit Pulping Machine

- Citrus Photo Electronic Grading Line

- Automatic Apple Weight Sorting Machine

- Raisin Color Sorting Machine

- Citrus Waxing Machine

- Fruit Washing Drying Waxing Grading Sorting Machine

- Industrial Grape Crusher Destemmer

- Grape Crusher Destemmer

- Automatic Grape Crusher Destemmer Machine

- Hotting Selling Garlic Harvester

- Juice And Paste Production Packing Line

- Automatic Banana Milk Filling Machine

- Industrial Stainless Steel Fruit Juice Milk Vacuum Degassing tank

- Soya-Bean Milk Self-Supporting Bag Filling Machine

- Complete Fruit Juice Processing Line

- Juice Filter Bag Filter Machine

- Fruit Juice Production Line

- Beverage Equipment apple Juicer Belt Machine

- Apple Orange Fruit Juice Production Line

- Fruit Juice Processing Line

- Apple Orange Fruit Juice Production Line Filling Packing Machine

- Milk Deaerator Machine

- Fruit Juicer Machine

- Fruit Chips Dehydrated Vegetable Production Line

- Industrial Vacuum Frying Machine

- Potato Chips Slicing Cutting Machine

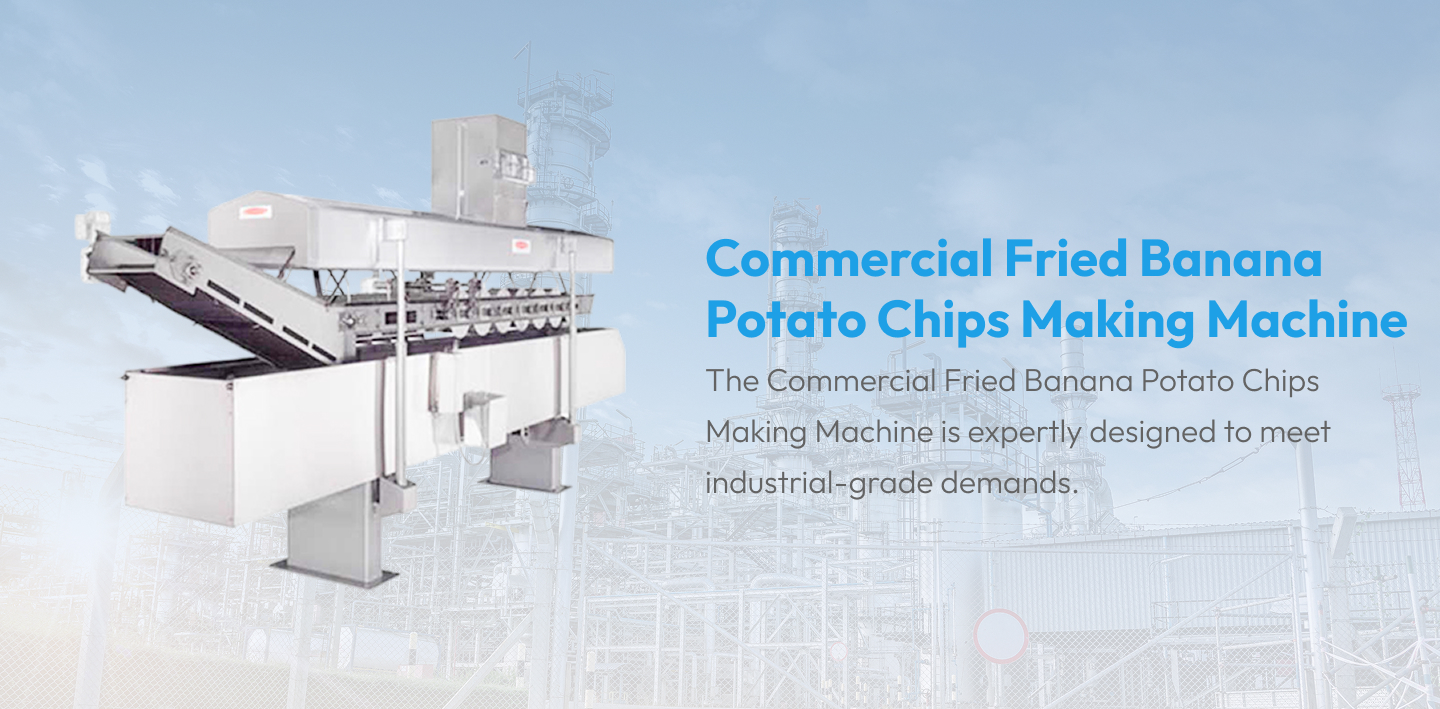

- Commercial Fried Banana Potato Chips Making Machine

- Electric Potato Chips Cutter Machine

- Industrial Small Scale Potato Chips Machine

- Automatic Apple Chips Making Machine

- Dried apple Rings Production Line

- Baked Potato Crisp Cracker Plant

- Frozen French Fries Making Machine

- Banana Processing Line

- Automatic Fruit Peeling Machine

- Vacuum Frying Crisp Apple Chips Maker Production Line

- Canned Fruit And Fish Production Line

- Complete Canned Sardines Production Line

- Automatic Tomato Sauced Sardine Canning Machine

- Canned Fruit Cocktail Processing Production Line

- Rotary Retort Autoclave Sterilizer

- Automatic Peach In Syrup Production Line

- Standard Canned Baby Corn Process Line

- Automatic Canned Sweet Corn Industry Process Line

- Complete Canned Kiwi Fruit Canning Machine

- Canned Food Pasteurizing Machine

- Commercial Canned Pineapple Process Line

- High Efficiency Canned Pineapple Processing Plant

- Peach Canning Machine

- Beverage Production Line

- High Quality Fruit Jam Production Line

- Complete Mineral Water Processing Line

- Purified Water Treatment Line

- 3 In 1 Purified Drinking Water Filling Machine

- Automatic Pure Water Filling Machine

- Small Bottle Water Filling Machine

- 8000 Pcs Filling Machine

- Spraying Cooling Tunnel

- Cherry Jam Processing Line

- Purees Making Machine

- Fermentation Tank

- Mango Pulp Making Machine

- Container Filling And Packing Machine

- Automatic Preformed Pouch Ketchup Packing Machine

- Automatic Electric Container Ice Cream Filler

- Rotary Type Ice Cream Cup Filling Sealing Machine

- Filling And Sealing Machine

- Sealing Packing Machine

- Injecting Type Plastic Tube Ice Lolly Making Equipment

- Second Hand Vacuum Packing Machine

- VFFS Vertical Forming Filling Sealing Pouch Packing Machine

- Grinding Powder Packing Machine

- Complete Production Line

- Coffee Making Machine

- Fresh mango Cutting Machine

- Vegetable Pickles Production Line

- Complete Sardines In Oil Production Line

- Industrial Medical Tongue Depressor Production Line

- Tongue Depressor Processing Machine

- Pineapple Chips Making Machine

- Industrial Raisin Processing Line

- Bean Curd Packing Machine

- Raisin Processing Equipment

- Dry Fruit Processing Line

- Complete UHT Milk Processing Line

- Salt And Sugar Filter Press Evaporator Machine

- Grape Processing Machinery

- Automatic Fruit Press Belt Equipment

- Special Large Capacity Belt Press

- Hydraulic Cacao Bean Oil Press

- Automatic Co2 Distillation Avocado Oil Expeller

- Screw Press Oil Expeller

- Rose Hip Concentrate Machine

- Raspberry Juice Concentrate Machine

- Raspberry Juice Concentrate Machine

- Instant Coffee Powder Processing

- Coconut Oil Expeller

- Acai Juice Concentrate Machine

- Multi Crystallization Mono crystal rock lump sugar production line

- Food Freezing Machine Frozen Food Line

- SSD Series IQF Quick Freezing Refrigeration System

- Fruit And Vegetable Tunnel Freezer

- Tunnel Quick Freezer

- 3 Ton Industrial Ice Cube Making Machine

- Strawberry Quick Freezing Processing Line Machine

- Pomegranate Quick Freezing Processing Line Machine

- Small Automatic Ice Maker Machine

- 1560 KG Ice Cube Maker

- Ice Cube Making Machine

- 1 Ton Ice Cube Maker

- Solar-Powered Freshening Cold Room

- Industrial Cube Ice Maker

- Sterilization Machine

- Food Sterilizers Machine

- Industrial Food Sterilizer Machine

- Automatic Milk Pasteurizer Food Sterilizer Machine

- Atmosphere Food Retort Machine

- High Temperature Pouch Packaging Machine

- Hot Water Spraying Retort Machine

- Food Sterilizers Efficient Milk Processing Machinery

- Head Space Sterilizer

- Glass Bottle Tunnel Sterilization Machine

- Spray Cooling Sterilizing Tunnel

- Drying Equipment And Fruit Powder Machine

- Industrial Dehydrated Fruit Vegetable Drying Machine

- Fruit Drying Machine

- Herb Microwave Vacuum Dryer

- Vacuum Drying Oven With Tray

- Freeze Dryer Lyophilizer Machine

- Large-Scale Vacuum Freeze Dryer

- Food Vacuum Dehydrator

- Microwave Pumpkin Powder Sterilizer Drying Dryer Machine

- Pumpkin Flour Process Machine

- Nut And Grain Processing Machine

- Salt Plant Chemicals Machine

- Fermentor Bioreactor

- Salt Production Processing Line Plant

- Complete Sliced Pineapple Canning Machine

- Pickled Cucumber Washing Canning Making Machine

- Iodized Salt Production Line

- Iodized Salt Production Machine

- Iodized Sea Salt Production Line

- Small Scale Iodized Salt Production Line

- Iodized Salt Refining Processing Plant Line

- Meat Fish And Egg Processing Line

- Grains And Tubers Plant

- Snack Production Line

- Essential Oil Extracting And Distillation Machine

- Contact Us

About

Shanghai Genyond Technology Co. Ltd

Since 2013, we have been delivering highly efficient and reliable Honey Concentration Machine, Soy Milk Filling Machine, UHT Milk Production Line, French Fries Cutting Machine, Sealing Packing Machine, Purified Water Treatment Line, Fruit Juicer Machine, etc.

Shanghai Genyond Technology Co. Ltd

Shanghai Genyond Technology Co. Ltd is a global name in the field of food processing machinery and equipment. Headquartered in Minhang, Shanghai, we have been serving the industry since 2013 with advanced engineering and high-quality manufacturing. We provide Honey Concentration Machine, Soy Milk Filling Machine, UHT Milk Production Line, Fruit Leather Cut Machine, French Fries Cutting Machine, Fruit Juicer Machine, Purified Water Treatment Line, Sealing Packing Machine, etc. Our company is dedicated to delivering efficient, innovative, and customized machinery solutions that empower food manufacturers to increase productivity and maintain high safety standards.Exporting Worldwide with Confidence

As a reputable exporter, Shanghai Genyond Technology Co. Ltd serves clients in over 30 countries across Asia, Europe, the Americas, and Africa.

Why We Stand Out?

Over a Decade of Experience: Established expertise in food processing machinery since 2013.A promise to offer products with higher quality standards.

Every product is manufactured with precision and undergoes rigorous quality checks to ensure compliance with international standards. We serve clients globally, offering flexible and reliable equipment designed to increase efficiency and reduce operational costs.

Popular Products

Our production facility is equipped with cutting-edge technology and skilled personnel who maintain strict quality control at every stage.We adhere to international manufacturing standards